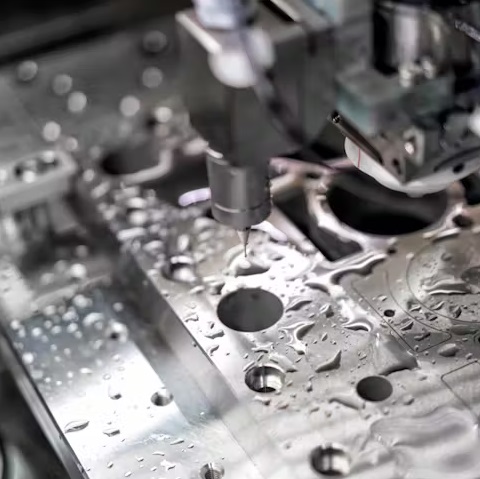

A rapid machining project will follow a defined process to ensure the production of a high-quality component. The project begins with CAD design. Our team of experts works together to optimize the CAD design to allow faster and cheaper machining. Once the CAD design has been optimized for machining, we select the best material for the purpose. This is primarily a function of the component’s intended application and the cost but is also influenced by factors such as the component’s geometry. For rapid machining, materials that are easily machinable are prioritized. This could be a range of plastics or metals, which cover an incredibly wide band of costs and properties. Before getting started on manufacturing the part, the CNC programming takes place. Each step that the CNC machine will perform is provided, with details such as the tool to use, the geometry of the tool movement, the feeds and speeds, and the tool offset. This critical task of CNC programming is made easier and quicker with CAM (computer-aided manufacturing) software. For rapid machining, specific use of high-speed roughing approaches and high-torque machines are employed. With the CNC programming complete, the machining of the selected material begins. Finishing processes are then done to ensure a high-quality final product and carry out further machining, grinding, boring, or polishing for high-precision tolerances.